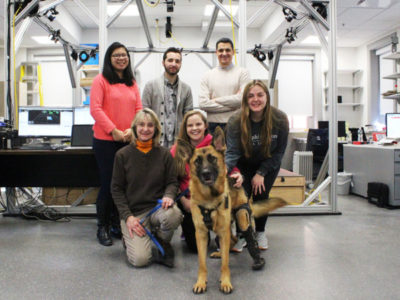

Buddy the German Shepherd has gone bionic thanks to IEEE-HKN Iota Delta Chapter and volunteers at the Stevens Institute of Technology in Hoboken, NJ. Severely injured, 1-year-old puppy Buddy was abandoned outside of an animal care facility in early May 2018 in Eastern New York. He managed to trap his back leg in a stray wire, and after his leg became painfully infected Buddy was forced to gnaw off his hind foot and part of his ankle. In order to save Buddy’s life his veterinary team opted to amputate the bottom half of his back leg, but lacked the technology to fit him for a prosthesis that would grant him full range of motion. With his current prosthesis, Buddy would eventually face painful hip problems that would likely degrade the use of his hind legs. That’s when IEEE-HKN Iota Delta Chapter and student volunteers team came to the rescue, thanks to an EPICS in IEEE grant.

With a budget of $10,000, the team set out to create a completely functional trans-tibial (below the knee) dog prosthesis. This massive undertaking had never before been successfully completed due to lack of research, cost limitations, and the weight of the prosthesis itself. However, recent developments in prosthetic components, such as sensors, controllers, and compact battery packs, made it possible to begin developing a fully-functional, motorized prosthesis. Inspired by major advancements in wearable robotics for humans, the team set out to create an adaptive, rugged model that could be modified to fit different sizes of dogs and serve their unique needs.

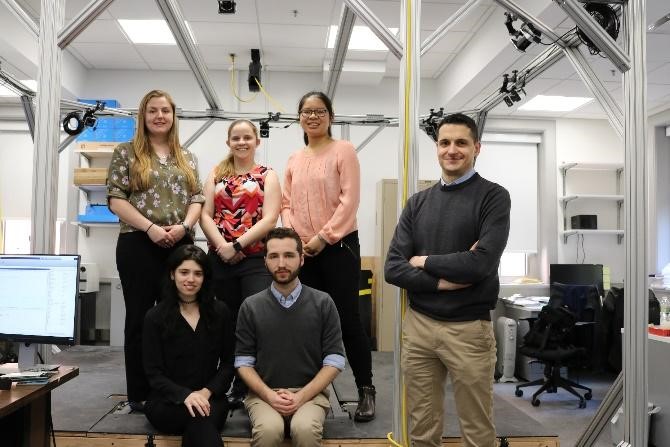

Setting: Zanotto’s Wearable Robotic Systems Lab

Top, left to right: Tiffany McGinness, Mariana Bomfim, Mey Olivares Tay

Bottom, left to right: Maria Cruz Campos, Matthew McGinn, Prof. Damiano Zanotto

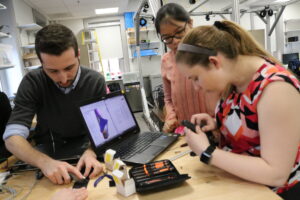

Lead by faculty advisor Dr. Damiano Zanotto (Stevens Institute of Technology, Wearable Robotics System Labs), the team embarked on their journey. They began by reading the minimal scientific literature on canine prosthetics and gait, and ultimately decided to collect data of their own. Zanotto mentioned that one of the highlights for the team was getting to meet Buddy in person to measure his gait and collect critical quantitative data (alongside some extra play time and petting.)  The team first created an alpha prototype that focused on the geometry and fit of the prosthesis. Rather than use traditional plaster casts to customize the new prosthesis, the team turned to a more efficient, high-tech approach: 3D-modeling. Thanks to advancements in rapid prototyping technologies, especially 3D scanners and printers, prostheses could be more easily customized and altered.

The team first created an alpha prototype that focused on the geometry and fit of the prosthesis. Rather than use traditional plaster casts to customize the new prosthesis, the team turned to a more efficient, high-tech approach: 3D-modeling. Thanks to advancements in rapid prototyping technologies, especially 3D scanners and printers, prostheses could be more easily customized and altered.

The project is due to launch a fully-functional model in summer 2020, but their impact doesn’t stop there. The project team is partnering with the Center for Innovation in Engineering and Science Education (CIESE) to expose teachers and K-12 students to robotics. They intend to collaborate with CIESE’s NDF ITEST Scale-Up project, that uses robotics as a tool to reach between 6,000-111,000 high school students. They hope to engage students at every age, not only to expose them to advancements in robotics, but also to allow them to understand STEM-centered careers are both exciting and attainable. The team will showcase and demonstrate the prototype robotic prosthesis to K-12 students both in a classroom setting and in a summer 2020 camp program during a hands-on laboratory robotics session.

This team challenged the notion that motorized canine prostheses had to be exorbitantly expensive. They put great minds and collaboration to work, not only to help Buddy, but to finally create a customizable powered prosthesis for man’s best friend.

Recent Comments